Publications

Filter by type:

Influence of co-deposition strategy on the mechanical behavior of additively manufactured functionally integrated materials

Abstract

The co-deposition of multiple powder feedstocks during metal additive manufacturing (AM) can be used to fabricate materials with spatially dependent properties, which can be engineered to contain different function- alities (i.e., functionally integrated materials, FIMs). Although the transition region that forms between dissimilar materials has been studied in detail, the influence of co-deposition on the resultant spatial phase distribution and associated mechanical behavior has heretofore not been reported. In this study, FIM samples transitioning from stainless steel (SS) 316 L to Haynes 282 Ni-based superalloy were deposited via directed energy deposition (DED). The FIM samples were compared to baseline, homogeneous single-alloy deposited samples using digital image correlation during tensile testing, together with microscopy, energy-dispersive X-ray spectroscopy, elec- tron backscattered diffraction, and thermodynamic modeling, to assess the performance of different co- deposition strategies. Each FIM sample exhibited a compositionally and microstructurally unique transition re- gion from SS 316 L to Haynes 282, which was found to have implications on the strain localization across the transition region during uniaxial tensile loading. Finer step sizes in co-deposition were found to minimize strain localization by avoiding sharp compositional interfaces in the transition region.

Design, material, function, and fabrication of metamaterials

Abstract

Metamaterials are engineered materials with unusual, unique properties and advanced functionalities that are a direct consequence of their microarchitecture. While initial properties and functionalities were limited to optics and electromagnetism, many novel categories of metamaterials that have applications in many different areas of research and practice, including acoustic, mechanics, biomaterials, and thermal engineering, have appeared in the last decade. This editorial serves as a prelude to the special issue with the same title that presents a number of selected studies in these directions. In particular, we review some of the most important developments in the design and fabrication of metamaterials with an emphasis on the more recent categories. We also suggest some directions for future research.

Deformation behavior of cell walls in an additively manufactured hybrid metallic foam

Abstract

A hybrid Al-Al3Ni metallic foam was synthesized in-situ via directed energy deposition (DED) of Ni-coated Al 6061 powder, without the need for a foaming agent. Three-dimensional characterization via X-ray computed tomography shows that the foam contains approximately 61.5 % porosity and a high volume fraction of the Al3Ni phase (~60 vol. %) within the cell walls. This microstructure is notably distinct from the eutectic structure that is typically observed in conventionally processed Al-Ni alloys. To investigate the mechanical properties and deformation mechanisms of the Al-Al3Ni cell walls, in-situ micro-pillar compression was performed, and the results reveal a notable yield strength of 560 MPa and a compressive strain that exceeds 30 %. These properties are attributable to the presence of a high volume fraction of Al3Ni particles, in combination with the charac- teristics of the Al/Al3Ni interfaces. To provide insight into the deformation mechanisms in the cell walls we used in-situ mechanical testing, transmission electron microscopy and precession electron diffraction characterization, together with molecular dynamics simulations. Our results reveal two distinct mechanisms: uniform dislocation- based deformation of the Al alloy phase and localized deformation within the slip bands in the Al3Ni phase. The results further highlight the importance of the Al/Al3Ni interfaces in mechanical strengthening and the transfer of plastic deformation from the Al phase to the Al3Ni phase. At high mechanical loads, cracks form due to the large stress concentration at the slip bands and slip band intersections in the Al3Ni, giving rise to intragranular fracture of Al3Ni and finally interfacial debonding and cracking.

Nanoarchitected metal/ceramic interpenetrating phase composites

Abstract

Architected metals and ceramics with nanoscale cellular designs, e.g., nanolattices, are currently subject of extensive investigation. By harnessing extreme material size effects, nanolattices demonstrated classically inaccessible properties at low density, with exceptional potential for superior lightweight materials. This study expands the concept of nanoarchitecture to dense metal/ceramic composites, presenting co-continuous architectures of three- dimensional printed pyrolytic carbon shell reinforcements and electrodeposited nickel matrices. We demonstrate ductile compressive deformability with elongated ultrahigh strength plateaus, resulting in an extremely high combination of compressive strength and strain energy absorption. Simultaneously, property-to-weight ratios outperform those of lightweight nanolattices. Superior to cellular nanoarchitectures, interpenetrating nanocom- posites may combine multiple size-dependent characteristics, whether mechanical or functional, which are radically antagonistic in existing materials. This provides a pathway toward previously unobtainable multifunctionality, extending far beyond lightweight structure applications.

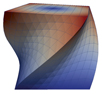

Minimal Surface-Based Materials for Topological Elastic Wave Guiding

Abstract

Materials based on minimal surface geometries have shown superior strength and stiffness at low densities, which makes them promising continuous-based material platforms for a variety of engineering applications. In this work, it is demonstrated how these mechanical properties can be complemented by dynamic functionalities resulting from robust topological guiding of elastic waves at interfaces that are incorporated into the consid- ered material platforms. Starting from the definition of Schwarz P minimal surface, geometric parametrizations are introduced that break spatial sym- metry by forming 1D dimerized and 2D hexagonal minimal surface-based materials. Breaking of spatial symmetries produces topologically non-trivial interfaces that support the localization of vibrational modes and the robust propagation of elastic waves along pre-defined paths. These dynamic prop- erties are predicted through numerical simulations and are illustrated by performing vibration and wave propagation experiments on additively manu- factured samples. The introduction of symmetry-breaking topological inter- faces through parametrizations that modify the geometry of periodic minimal surfaces suggests a new strategy to supplement the load-bearing properties of this class of materials with novel dynamic functionalities.

Damage tolerance in additively manufactured ceramic architected materials

Abstract

Technical ceramics exhibit exceptional high-temperature properties, but unfortunately their extreme crack sensitivity and high melting point make it challenging to manufacture geometrically complex structures with sufficient strength and toughness. Emerging additive manufacturing technologies enable the fabrication of large- scale complex-shape artifacts with architected internal topology; when such topology can be arranged at the microscale, the defect population can be controlled, thus improving the strength of the material. Here, ceramic micro-architected materials are fabricated using direct ink writing (DIW) of an alumina nanoparticle-loaded ink, followed by sintering. After characterizing the rheology of the ink and extracting optimal processing parameters, the microstructure of the sintered structures is investigated to assess composition, density, grain size and defect population. Mechanical experiments reveal that woodpile architected materials with relative densities of 0.38–0.73 exhibit higher strength and damage tolerance than fully dense ceramics printed under identical conditions, an intriguing feature that can be attributed to topological toughening.

Alleviating expansion-induced mechanical degradation in lithium-ion battery silicon anodes via morphological design

Abstract

The mechanics of films undergoing volume expansion on curved substrates plays a key role in a variety of technologies including biomedical implants, thermal and environmental barrier coatings, and electrochemical energy storage systems. Silicon anodes for lithium-ion batteries are an especially challenging case because they can undergo volume variations up to 300% that results in cracking, delamination, and thus significant loss in performance. In this study, we use finite element analysis to model the volume expansion during lithiation for silicon coated on spinodal, inverse opal, gyroid, and Schwartz primitive nickel backbones and compare the distributions of maximum principal stress, strain energy density, and von Mises stress, which we use as indicators for propensity for cracking, delamination, and yielding, in order to explore the effect of backbone morphology on mechanical degradation during expansion. We show that, when compared to the inverse opal, the spinodal morphology reduces and uniformly distributes the maximum principal stress and strain energy density in the silicon layer, and delays the onset of expansion-induced yielding at all silicon layer thicknesses, which we ascribe to the unique interfacial curvature distribution of spinodal structures. This work highlights the importance of morphology on coatings undergoing volume variations and unveils the particular promise of spinodally derived materials for the design of next generation lithium-ion battery electrodes.

Thickness-Dependent Microstructure in Additively Manufactured Stainless Steel

Abstract

Widespread industrial adoption of metal additive manufacturing (AM) requires an in-depth understanding of microstructural evolution during AM. In this study, the effect of process parameters and feature thickness on the microstructures of 316L stainless steel components fabricated by laser powder bed fusion (LPBF) was examined. A standard benchmark geometry developed by the National Institute of Standards and Technology, which contained walls of 0.5, 2.5 and 5.0 mm in thickness, was used. Optical microscopy, finite element analysis, scanning electron microscopy and electron backscatter diffraction revealed dramatic microstructural differences in features of different thickness within the same component. The feature thickness influenced the cooling rate, which in turn impacted the melt pool size, solidification microstructure, grain morphology and density of geometrically necessary dislocations. The relationship between feature size and grain morphology was dependent on the energy input used during LPBF. Such behavior suggested that local manipulation of LPBF process parameters can be employed to achieve microstructural homogeneity within the as-printed stainless steel components.

Tensegrity Metamaterials: Toward Failure-Resistant Engineering Systems through Delocalized Deformation

Abstract

Failure of materials and structures is inherently linked to localized mechanisms, from shear banding in metals, to crack propagation in ceramics and collapse of space-trusses after buckling of individual struts. In lightweight structures, localized deformation causes catastrophic failure, limiting their application to small strain regimes. To ensure robustness under real-world nonlinear loading scenarios, overdesigned linear-elastic constructions are adopted. Here, the concept of delocalized deformation as a pathway to failure-resistant structures and materials is introduced. Space-tileable tensegrity metamaterials achieving delocalized deformation via the discontinuity of their compression members are presented. Unprecedented failure resistance is shown, with up to 25-fold enhancement in deformability and orders of magnitude increased energy absorption capability without failure over same-strength state-of-the-art lattice architectures. This study provides important groundwork for design of superior engineering systems, from reusable impact protection systems to adaptive load-bearing structures.

A press release on this article is available here.

A link to a video emphasizing the main concept of this work can be found here.

Nanoscale investigation of two-photon polymerized microstructures with tip-enhanced Raman spectroscopy

Abstract

We demonstrate the use of tip-enhanced Raman spectroscopy (TERS) on polymeric microstructures fabricated by two-photon polymerization direct laser writing (TPP-DLW). Compared to the signal intensity obtained in confocal Raman microscopy, a linear enhancement of almost two times is measured when using TERS. Because the probing volume is much smaller in TERS than in confocal Raman microscopy, the effective signal enhancement is estimated to be ca. 10^4. We obtain chemical maps of TPP microstructures using TERS with relatively short acquisition times and with high spatial resolution as defined by the metallic tip apex radius of curvature. We take advantage of this high resolution to study the homogeneity of the polymer network in TPP microstructures printed in an acrylic-based resin. We find that the polymer degree of conversion varies by about 30% within a distance of only 100 nm. The combination of high resolution topographical and chemical data delivered by TERS provides an effective analytical tool for studying TPP-DLW materials in a non-destructive way.

Mechanically Compliant Thermal Interfaces Using Biporous Copper-Polydimethylsiloxane Interpenetrating Phase Composite

Abstract

Thermal interface materials are essential for thermal management in electronics packaging by providing a low resistance thermal pathway between heat sources and heat sinks. Nanostructured materials can be potential candidates for the next-generation interface materials by coupling their high thermal conductivity and mechanical compliance, suppressing failure even after large numbers of thermal cycles. This work investigates the thermal and mechanical characteristics of a new type of thermal interface materials, consisting of metal/elastomer interpenetrating phase composites. The 3D, highly porous copper scaffolds are fabricated via a fast and simple in situ bubble-templated electrodeposition process without the presence of solid templates; subsequently, the void fraction of the composite is filled by elastomer infiltration. The presence of elastomer matrix demonstrates limited impact on the thermal conductivity of the composite while it contributes substantially to the mechanical properties, providing the structural flexibility required. Thermal resistance values of 1.2–4.0 cm^2 K W^-1 are measured upon multiple thermal cycles, confirming the mechanical stability of the composite, without showing any noticeable degradation.

Mechanical performance of 3D printed interpenetrating phase composites with spinodal topologies

Abstract

The mechanical response of interpenetrating phase composites (IPCs) with stochastic spinodal topologies is investigated experimentally and numerically. Model polymeric systems are fabricated by Polyjet multi‐material printing, with the reinforcing phase taking the topology of a spinodal shell, and the remaining volume filled by a softer matrix. We show that spinodal shell IPCs have comparable compressive strength and stiffness to IPCs with two well‐established periodic reinforcements, the Schwarz P triply periodic minimal surface (TPMS) and the octet truss‐lattice, while exhibiting far less catastrophic failure and greater damage resistance, particularly at high volume fraction of reinforcing phase. The combination of high stiffness and strength and a long flat plateau after yielding makes spinodal shell IPCs a promising candidate for energy absorption and impact protection applications, where the lack of material softening upon large compressive strains can prevent sudden collapse. Importantly, in contrast with all IPCs with periodic reinforcements, spinodal shell IPCs are amenable to scalable manufacturing via self‐assembly techniques.

Architected implant designs for long bones: Advantages of minimal surface-based topologies

Abstract

Large bone fractures often require porous implants for complete healing. In this work, we numerically investigate the suitability of three topologically very different architected materials for long bone implants: the octet truss-based lattice, the Schwartz P minimal surface-based lattice and the spinodal stochastic surface-based lattice. Each implant topology (reinforcement) and its surrounding tissue (soft matrix) are modeled as a composite system via finite element analysis. Performance metrics are defined based on the Young’s modulus, the peak stress under service conditions, the interfacial surface area per unit volume and the relative bone growth rate (estimated based on the strain transferred to the soft matrix). We show that surface-based topologies are less prone to fatigue failure and may promote supe- rior bone growth than conventional truss-based designs. Spinodal surface-based architected materials have the best performance, and can be fabricated via self-assembly approaches followed by material con- version, potentially allowing scalable fabrication of implants with unit cell sizes at the micro-scale, thus dramatically amplifying surface area per unit volume and bone growth efficiency.

Thermal post-curing as an efficient strategy to eliminate process parameter sensitivity in the mechanical properties of two-photon polymerized materials

Abstract

Two-photon polymerization direct laser writing (TPP-DLW) is one of the most versatile technologies to additively manufacture complex parts with nanoscale resolution. However, the wide range of mechanical properties that results from the chosen combination of multiple process parameters imposes an obstacle to its widespread use. Here we introduce a thermal post-curing route as an effective and simple method to increase the mechanical properties of acrylate-based TPP-DLW-derived parts by 20-250% and to largely eliminate the characteristic coupling of processing parameters, material properties and part functionality. We identify the underlying mechanism of the property enhancement as a self-initiated thermal curing reaction, which robustly facilitates the high property reproducibility that is essential for any application of TPP-DLW.

Surface oxide and hydroxide effects on aluminum microparticle impact bonding

Abstract

Oxides, hydroxides, and other surface films act as impediments to metallurgical bonding during cold spray impact adhesion, raising the critical adhesion velocity and reducing the quality of the deposited coating. Using a single-particle impact imaging approach we study how altering the passivating surface oxides with exposures to various levels of heat and humidity affect the cold spray critical adhesion veloc- ity in the case of aluminum. We analyze the thickness, composition and microstructure of the passivation layers with transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS), and Fourier- transform infrared spectroscopy (FTIR), and correlate our observations with a direct measurement of the critical adhesion velocity for each surface treatment. We conclude that exposures to temperatures as high as 300 °C for up to 240 min in dry air, or to room-temperature with humidity levels as high as 50% for 4 days, have negligible effect on the surface oxide layers, and by extension do not affect the critical adhesion velocity. In contrast, ambient-temperature exposure to 95% relative humidity levels for 4 days increases the critical adhesion velocity by more than 125 m/s, approximately a 14% percent increase. We observe that this distinct change in critical adhesion velocity is correlated with unique changes in the passivating layer thickness, thickness uniformity, crystallinity and composition resulting from exposure to high humidity. These results speak to particle surface treatments to improve the cold spray process.

Plate-nanolattices at the theoretical limit of stiffness and strength

Abstract

Though beam-based lattices have dominated mechanical metamaterials for the past two decades, low structural efficiency limits their performance to fractions of the Hashin-Shtrikman and Suquet upper bounds, i.e. the theoretical stiffness and strength limits of any isotropic cellular topology, respectively. While plate-based designs are predicted to reach the upper bounds, experimental verification has remained elusive due to significant manufacturing challenges. Here, we present a new class of nanolattices, constructed from closed-cell plate-architectures. Carbon plate-nanolattices are fabricated via two-photon lithography and pyrolysis and shown to reach the Hashin-Shtrikman and Suquet upper bounds, via in situ mechanical compression, nano-computed tomography and micro-Raman spectroscopy. Demonstrating specific strengths surpassing those of bulk diamond and average performance improvements up to 639% over the best beam-nanolattices, this study provides detailed experimental evidence of plate architectures as a superior mechanical metamaterial topology.

See an exciting Seeker video on this work: https://youtu.be/0KJjs4W09hQ

Minisurf – A minimal surface generator for finite element modeling and additive manufacturing

Abstract

Triply periodic minimal surfaces (TPMSs) have long been studied by mathematicians but have recently garnered significant interest from the engineering community as ideal topologies for shell-based architected materials with both mechanical and functional applications. Here, we present a TPMS generator, MiniSurf. It combines surface visualization and CAD file generation (for both finite element modeling and additive manufacturing) within one single GUI. MiniSurf presently can generate 19 built-in and one user-defined triply periodic minimal surfaces based on their level-set surface approximations. Users can fully control the periodicity and precision of the generated surfaces. We show that MiniSurf can potentially be a very useful tool in designing and fabricating architected materials.

Enhanced adhesion in two-photon polymerization direct laser writing

Abstract

We have quantified the adhesion forces between two-photon polymerization direct laser writing (TPP-DLW) microstructures and glass surfaces with and without an adhesion promoter. Glass surfaces treated with an acryloxy-silane agent produce adhesion forces that are almost three times larger than the forces observed with pristine glass surfaces. Determination of the substrates’ surface free energies suggests that the observed adhesion enhancement is chemical in its nature, implying that covalent bonds are formed between the polymer and the glass by means of the silane agent. The importance of this finding is demonstrated in the successful production of glassy carbon microstructures using TPP-DLW, followed by pyrolysis.

A versatile numerical approach for calculating the fracture toughness and R-curves of cellular materials

Abstract

We develop a numerical methodology for the calculation of mode-I R-curves of brittle and elastoplastic lattice materials, and unveil the impact of lattice topology, relative density and constituent material behavior on the toughening response of 2D isotropic lattices. The approach is based on finite element calculations of the J-integral on a single-edge-notch- bend (SENB) specimen, with individual bars modeled as beams having a linear elastic or a power-law elasto-plastic constitutive behavior and a maximum strain-based damage model. Results for three 2D isotropic lattice topologies (triangular, hexagonal and kagome) and two constituent materials (representative of a brittle ceramic (silicon carbide) and a strain hardening elasto-plastic metal (titanium alloy)) are presented. We extract initial frac- ture toughness and R-curves for all lattices and show that (i) elastic brittle triangular lat- tices exhibit toughening (rising R-curve), and (ii) elasto-plastic triangular lattices display significant toughening, while elasto-plastic hexagonal lattices fail in a brittle manner. We show that the difference in such failure behavior can be explained by the size of the plastic zone that grows upon crack propagation, and conclude that the nature of crack propaga- tion in lattices (brittle vs ductile) depends both on the constituent material and the lattice architecture. While results are presented for 2D truss-lattices, the proposed approach can be easily applied to 3D truss and shell-lattices, as long as the crack tip lies within the empty space of a unit cell.

Ultrahigh Energy Absorption Multifunctional Spinodal Nanoarchitectures

Abstract

Nanolattices are promoted as next-generation multifunctional high-performance materials, but their mechanical response is limited to extreme strength yet brittleness, or extreme deformability but low strength and stiffness. Ideal impact protection systems require high-stress plateaus over long deformation ranges to maximize energy absorption. Here glassy carbon nanospinodals, i.e., nanoarchitectures with spinodal shell topology, combining ultrahigh energy absorption and exceptional strength and stiffness at low weight. Noncatastrophic deformation up to 80% strain, and energy absorption up to one order of magnitude higher than for other nano-, micro-, macro-architectures and solids, and state-of-the-art impact protection structures are shown. At the same time, the strength and stiffness are on par with the most advanced yet brittle nanolattices, demonstrating true multifunctionality. Finite element simulations show that optimized shell thickness-to-curvature-radius ratios suppress catastrophic failure by impeding propagation of dangerously oriented cracks. In contrast to most micro- and nano-architected materials, spinodal architectures may be easily manufacturable on an industrial scale, and may become the next generation of superior cellular materials for structural applications.

This article was reviewed in Science by Senior Editor Marc Lavine.

Thermal transport in hollow metallic microlattices

Abstract

While over the past decade architected cellular materials have been shown to possess unique mechanical properties, their thermal properties have received relatively little attention. Here, we investigate thermal transport in hollow nickel microlattices as a function of temperature and mechanical loading using infrared thermography. The effective thermal conductivity of hollow nickel microlattices with 99.9% porosity and 1 µm layer thickness is as low as 0.049 W m−1 K−1 at 320 K and increases to 0.075 W m−1 K−1 at 480 K, an increase we attribute to internal thermal radiation. By measuring the emissivity and using the Stephan-Boltzmann law, we estimate the contribution of thermal radiation in the effective thermal conductivity to range from 20% at 320 K to 49% at 480 K. The high porosity of microlattices strongly limits solid conduction and makes surface radiation very important in thermal transport. We further explore the impact of the strut surface condition by comparing hollow doped nickel microlattices with a smooth surface to those with a rough surface: the emissivity increases from 0.24 to 0.43, leading to increased thermal radiation contributions of 41% at 320 K to 58% at 480 K. Under mechanical loading, as the strain increases from 0% to 50%, decreasing the angle between the struts and the horizontal plane from 60° to 38°, the effective thermal conductivity decreases from 0.049 W m−1 K−1 to 0.016 W m−1 K−1. These findings indicate that architected cellular materials provide an excellent platform to control thermal properties independently on mechanical properties and to potentially develop thermal and thermomechanical metamaterials.

The mechanical response of cellular materials with spinodal topologies

Abstract

The mechanical response of cellular materials with spinodal topologies is numerically and experimentally investigated. Spinodal microstructures are generated by the numerical solution of the Cahn-Hilliard equation. Two different topologies are investigated: ‘solid models,’ where one of the two phases is modeled as a solid material and the remaining volume is void space; and ‘shell models,’ where the interface between the two phases is assumed to be a solid shell, with the rest of the volume modeled as void space. In both cases, a wide range of relative densities and spinodal characteristic feature sizes are investigated. The topology and morphology of all the numerically generated models are carefully characterized to extract key geometrical features and ensure that the distribution of curvatures and the aging law are consistent with the physics of spinodal decomposition. Finite element meshes are generated for each model, and the uniaxial compressive stiffness and strength are extracted. We show that while solid spinodal models in the density range of 30-70% are relatively inefficient (i.e., their strength and stiffness exhibit a high-power scaling with relative density), shell spinodal models in the density range of 0.01-1% are exceptionally stiff and strong. Spinodal shell materials are also shown to be remarkably imperfection insensitive. These findings are verified experimentally by in-situ uniaxial compression of polymeric samples printed at the microscale by Direct Laser Writing (DLW). At low relative densities, the strength and stiffness of shell spinodal models outperform those of most lattice materials and approach theoretical bounds for isotropic cellular materials. Most importantly, these materials can be produced by self-assembly techniques over a range of length scales, providing unique scalability.

Scalable synthesis of gyroid-inspired freestanding three-dimensional graphene architectures

Abstract

Three-dimensional porous architectures of graphene are desirable for energy storage, catalysis, and sensing applications. Yet it has proven challenging to devise scalable methods capable of producing co-continuous architectures and well-defined, uniform pore and ligament sizes at length scales relevant to applications. This is further complicated by processing temperatures necessary for high quality graphene. Here, bicontinuous interfacially jammed emulsion gels (bijels) are formed and processed into sacrificial porous Ni scaffolds for chemical vapor deposition to produce freestanding three-dimensional turbostratic graphene (bi-3DG) monoliths with high specific surface area. Scanning electron microscopy (SEM) images show that the bi-3DG monoliths inherit the unique microstructural characteristics of their bijel parents. Processing of the Ni templates strongly influences the resultant bi-3DG structures, enabling the formation of stacked graphene flakes or fewer-layer continuous films. Despite the multilayer nature, Raman spectra exhibit no discernable defect peak and large relative intensity for the Raman 2D mode, which is a characteristic of turbostratic graphene. Moiré patterns, observed in scanning tunneling microscopy images, further confirm the presence of turbostratic graphene. Nanoindentation of macroscopic pillars reveals a Young’s modulus of 30 MPa, one of the highest recorded for sp2 carbon in a porous structure. Overall, this work highlights the utility of a scalable self-assembly method towards porous high quality graphene constructs with tunable, uniform, and co-continuous microstructure.

Programmable Mechanical Properties of Two-Photon Polymerized Materials: From Nanowires to Bulk

Abstract

Two-photon polymerization direct laser writing (TPP-DLW) is the most promising technology for additive manufacturing of geometrically complex parts with nanoscale features, and could dramatically accelerate the development of a wide range of engineering micro/nanosystems. However, a major obstacle to TPP-DLW’s widespread industrial adoption is the lack of systematic data on material properties and limited knowledge on their correlation with processing parameters. These correlations for the acrylate-based resin IP-Dip are experimentally established over a large range of process parameters and length scales ranging from nanometers to centimeters. Universal characteristic relations between mechanical properties and process parameters are identified, which enable the tailoring of the material strength and stiffness over half an order of magnitude from rubbery soft to hard and strong. With a threshold-based optics model presented herein, the mechanical properties of the two-photon polymerized material can be accurately captured as a function of the applied process parameters, laying the foundation for a universal quantitative predictability of two-photon polymerization with programmable mechanical properties. This knowledge enables fabrication of microscale components with tailored local gradients in their mechanical properties, with significant implications for the development of novel mechanical, photonic, and photonic metamaterials.

Negative-Stiffness Inclusions as a Platform for Real-Time Tunable Phononic Metamaterials

Abstract

We propose an approach for real-time manipulation of low-frequency phononic band gaps in a metamaterial without affecting the material geometry, microarchitecture, or the crystal structure of the base material. Metamaterials with tunable band gaps are realized by introducing periodically arranged negative-stiffness inclusions, the modulus of which can be varied in time in order to modify the metamaterial macroscopic stiffness in certain directions without bringing the material to the point of elastic instability or inducing extreme geometric change. The evolution of band gaps is investigated numerically, and the proposed concept is verified experimentally in a lattice prototype with magnetic elements functioning as negative-stiffness units. Design guidelines for achieving a real-time tunable phononic band gap are also presented.

Multiscale modeling and optimization of the mechanics of hierarchical metamaterials

Abstract

We present a survey of modeling techniques used to describe and predict architected cellular metamaterials, and to optimize their topology and geometry toward tailoring their mechanical properties such as stiffness, strength, fracture toughness, and energy absorption. Architectures of interest include truss-, plate-, and shell-based networks with and without periodicity, whose effective mechanical behavior is simulated by tools such as classical finite elements, further scale-bridging techniques such as homogenization and concurrent scale-coupling, and effective continuum descriptions of the underlying discrete networks. In addition to summarizing advances in applying the latter techniques to improve the properties of metamaterials and featuring prominent examples of structure–property relations achieved this way, we also present recently introduced techniques to improve the optimization process toward a full exploitation of the available design space, accounting for both linear and nonlinear material behavior.

Magnetoelastic Metamaterials for Energy Dissipation and Wave Filtering

Abstract

A novel magnetoelastic mechanical metamaterial consisting of a hyperelastic 2D lattice incorporating permanent magnets is presented and characterized. When properly designed and fabricated, the metamaterial possesses two stable equilibrium configurations (henceforth referred to as hexagonal/hourglass and kagome), both stretching dominated (and hence stiff ). The two configurations have significantly different elastic properties and wave propagation characteristics, as shown numerically and experimentally. By switching between the two configurations via uniaxial loading cycles, the material displays hysteresis, thus dissipating substantial amounts of energy; in contrast with purely mechanical bistable structures (e.g., arches, hinged beams and buckled beams), the proposed magnetoelastic metamaterial does not require multiple unit cells in series or stiff boundary conditions to exhibit energy dissipation, thus enabling the implementation of compact stiff dampers. The presence of a bandgap in the kagome configuration (but not in the hexagonal/hourglass configuration) is attributed to an internal resonance mechanism and provides the foundation for the development of compact dynamic filters for mechanical signals.

Additive Manufacturing of Ductile, Ultrastrong Polymer-Derived Nanoceramics

Abstract

Ceramics would be ideal engineering materials if their brittleness and scattered fracture strength could be overcome. While ductility and extraordinary strength have been reported at the nanoscale, they both rapidly disappear when samples reach micrometer dimensions; furthermore, manufacturing is limited to elaborate approaches, which are purely scientific in nature. Here, we present a robust route to additively manufacture ductile, ultrastrong silicon oxycarbide (SiOC) via two-photon polymerization direct laser writing (TPP-DLW) of a preceramic resin and subsequent pyrolysis. We 3D-print micrometer-size pillars and architected materials with feature sizes down to ∼200 nm and characterize them under uniaxial compression. Independent of size, SiOC micropillars consistently deform plastically with strains up to 25% and strengths >7 GPa, across the entire range of examined diameters (1–20 μm). Our findings demonstrate straightforward fabrication of ductile, ultrastrong ceramics at previously unprecedented scales, potentially enabling manufacturing of engineering systems up to tens of millimeters in size.

The effect of manufacturing defects on compressive strength of ultralight hollow microlattices: A data-driven study

Abstract

Hollow microlattices constitute a model topology for architected materials, as they combine excellent specific stiffness and strength with relative ease of manufacturing. The most scalable manufacturing technique to date encompasses fabrication of a sacrificial polymeric template by the Self Propagating Photopolymer Waveguide (SPPW) process, followed by thin film coating and removal of the substrate. Accurate modeling of mechanical properties (e.g., stiffness, strength) of hollow microlattices is challenging, primarily due to the complex stress state around the hollow nodes and the existence of manufacturing-induced geometric imperfections (e.g. cracks, non-circularity, etc.). In this work, we use a variety of measuring techniques (SEM imaging, CT scanning, etc.) to characterize the geometric imperfections in a nickel-based ultralight hollow microlattice and investigate their effect on the compressive strength of the lattice. At the strut level, where a more quantitative description of geometric defects is available, the gathered data is used to build a stochastic field model of geometric imperfections using Proper Orthogonal Decomposition. Using Monte Carlo simulations, the critical buckling loads of a large set of imperfect bars created using the stochastic model are then extracted by Finite Elements Analysis. The statistics of the buckling strength in artificially generated bars is then used to explain the scatter in the strength of CT-derived bars and its correlation with the lattice strength measured experimentally. Although the quantitative results are specific to microlattices fabricated by SPPW templating, the methodology presented herein is equally applicable to architected materials produced by other manufacturing processes.

Hybrid Hollow Microlattices with Unique Combinations of Stiffness and Damping

Abstract

Hybrid micro-architected materials with unique combinations of high stiffness, high damping, and low density are presented. We demonstrate a scalable manufacturing pro- cess to fabricate hollow microlattices with a sandwich wall architecture comprising an elastomeric core and metallic skins. In this configuration, the metallic skins provide stiff- ness and strength, whereas the elastomeric core provides constrained-layer damping. This damping mechanism is effective under any strain amplitude, and at any relative den- sity, in stark contrast with the structural damping mechanism exhibited by ultralight metallic or ceramic architected materials, which requires large strain and densities lower than a fraction of a percent. We present an analytical model for stiffness and constrained-layer damping of hybrid hollow microlattices, and verify it with finite ele- ments simulations and experimental measurements. Subsequently, this model is adopted in optimal design studies to identify hybrid microlattice geometries which provide ideal combinations of high stiffness and damping and low density. Finally, a previously derived analytical model for structural damping of ultralight metallic microlattices is extended to hybrid lattices and used to show that ultralight hybrid designs are more efficient than purely metallic ones.